The high voltage (HV) supply was one of the first items to be designed and constructed, and has subsequently been modified quite a few times to become what is now a flexible and reliable source of high voltage and current at the line frequency of 50Hz (UK standard), and up to sustained power outputs of 1600W, and peak power outputs up to 2500W.

Note: A high voltage supply is capable of delivering voltages and currents, even at lower powers, that are instantly lethal, and that any design and operation of a high voltage unit should be undertaken with great care by a trained and experienced individual. In my own case I was trained to work with high voltage equipment early in my career as an electronic engineer, and hence have opted for experimental flexibility, and maximum configuration, a power supply build that is accessible, open, and where high voltages could externally be exposed to the operator at certain key points. Careful design, implementation, and operation of such a supply is for the full responsibility of the individual concerned.

In the early days of this research it was unclear to me where in the experimental circuit interesting and unusual electrical phenomena originated from, whether it was the product of the generator, the tuning and driving units, the experimental coils themselves, the driven loads, the surrounding environment, or a combination of these factors. Later in the research I discovered that the generation of particularly displacement related events required a number of pre-conditions to be established, which involved the balance of the electric and magnetic fields of induction, which in turn involves all of the above factors, combined with a non-linear trigger, and with a defined load or “need” that cannot be met through the process of transference. These pre-conditions and the details pertaining to the generation of a displacement event will be considered and written-up in subsequent posts.

It was considered central to the early research, in replicating the key measurements and observations of other significant works e.g. Dollard et al[1], that the generator design be as close as possible to those used, and especially considering that actual units and components may not be easily obtainable e.g. an original H.G. Fischer diathermy unit. However for this unit certain videos, internal pictures, and schematics where obtainable online and formed the basis of the first stage of building a suitable generator using easily obtainable parts and components. The overall generator to be used for experimentation is a combination of the HV supply detailed in this post, and driving a range of subsequent generator stages that transform the supplied HV AC voltage and currents at the line frequency, into higher frequency ac, oscillations, impulses, bursts, modulated waveforms, and other such driving waveforms as may be useful to the study of the displacement and transference of electric power.

Figures 1 show the HV supply which currently drives the different types of generator stages:

The circuit diagram for the HV supply is shown in Figure 2 below, or click here to view the high resolution version. The schematic should be referenced for the subsequent circuit description:

AC line power at UK standard 240V 50Hz is fed via a high current (16A) 3-pin connector to a domestic distribution box with 3 circuit breakers at 6A, 10A, and 20A. The 6A circuit breaker feeds a low voltage switched-mode power supply unit providing 15V @ 3A and is used to power low voltage circuits in the HV supply and the generator stage including, pre-amplifiers, fans, control electronics, measurement devices, indicators, meters, and any other low voltage units. The HV supply is arranged with a number of low voltage two-pin power jack sockets to supply low voltage generator stage requirements on the upper level. The 10A circuit breaker powers filament transformers for vacuum tube generator stages, and auxiliary devices requiring line voltage AC, via a suitable mains output connector in the form of shielded 3-pin connector, and ceramic connection block for ad-hoc connections. The 20A circuit breaker feeds the high voltage transformers via a suitable power controller.

The distribution unit also has space for an incoming line RCD breaker, but has subsequently been removed, as it was found to be too sensitive to some experiments where power is reflected back into the HV supply, and causing the RCD to cut the power during the experiment. As an alternative a larger RCD was incorporated into the mains distribution for the laboratory, and separate mains circuits fed via a UPS (uninterruptible power supply) to measurement and test equipment, and computers. This arrangement prevents sensitive equipment from inadvertently being switched-off and/or rebooted during certain experiments when the lab RCD would disengage to protect the input supply. Having the test equipment running under these circumstances has proved key to understanding conditions and events within the experiment that have caused large reflections back through the mains supply.

The 20A circuit is first passed through a high current line filter which is used to prevent higher frequency electrical disturbances from being reflected back into the mains supply, and offer a measure of isolation between the two. The output of the line filter is fed to a power controller which enables the variable control of power supplied to the high voltage transformers. This HV supply was specifically designed around the use of the microwave oven transformer (MOT) as the high voltage part of the supply. MOTs are very readily available, and have proved to be a strong and robust transformer for this type of supply. The transformers used are all Galanz GAL-900E based which nominally produce 2100VRMS @ 900W ~0.45ARMS, and are quite common in UK domestic microwave ovens. The MOT represents a significant inductive load to the incoming AC supply, and uncorrected will reduce the power factor from the ideal 1 to ~0.6. To correct for this and reduce the draw on the incoming supply a power factor correction (PFC) capacitor can be used at the AC line input (after the line filter and before the SCR). A 20µF AC PFC capacitor can be used in order to correct for a single MOT. For 2-3 MOTs being used together this can be increased to 40µF.

The MOT is a transformer designed to drive a specific impedance load, (magnetron via a voltage doubler and tuned with a series capacitor), with the minimum quantity, and hence cost, of copper, and with the cheapest and simplest manufacture methods and components. This leads to certain drawbacks in the transformer characteristics, and most especially saturation of the transformer core when driven open-circuit, or connected to a higher than intended load impedance. The core is cheaply manufactured from steel laminate and then welded together which shorts the laminates out, greatly increasing the core saturation rate when adequate power is not drawn from the transformer. A detailed study of the characteristics of the MOT has been presented by Wokoun[2].

The easy core saturation requires the current to be restricted in the primary coil. This is not easily done directly with a variac, as is usual for variable output control of a transformer, since the core easily saturates at low input primary voltages leading to large run-away currents in the primary, rapid core heating, and ultimately destruction of the transformer from excessive heating, not to mention the dangerous risk of a transformer fire which is very hard to deal with due to extreme heating of the steel core even after the power has been cut-off at the input. Instead the current must be restricted either via an inductive load in the primary circuit, or much better, an SCR power controller.

A suitable simple series inductor is the primary of another MOT, (with the secondary shorted), connected in series with the primary of the MOT to act as the HV transformer. Alternatively the secondary of another MOT, (with the primary shorted), can be connected in series with the secondary of the HV transformer MOT, but more heating tends to occur in this configuration from the higher secondary impedance. The series primary connected MOT was found to limit the output current to a degree, and made adjustment with an input variac possible, with less chance of core saturation, but with however limited overall range of adjustment and suitability to changing load impedance. The advantage however of this first method is that the output of the MOT (not in core saturation) is a complete sine wave. In core saturation the output becomes progressively distorted towards a heavily clipped sine wave. It was concluded that this method of power control would be too limited for the wide range of generators that the HV supply would be driving.

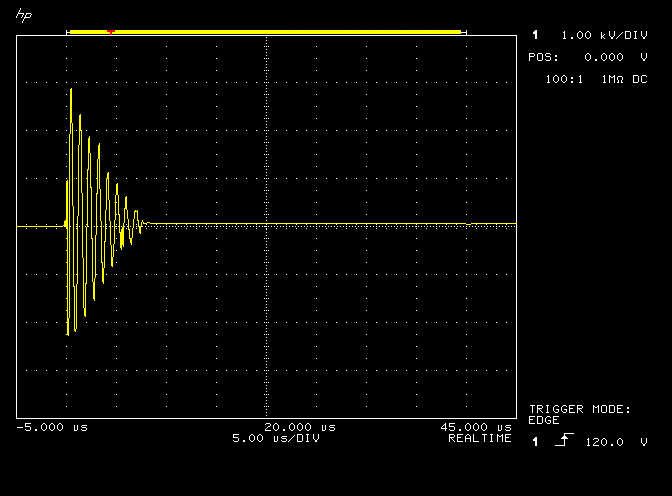

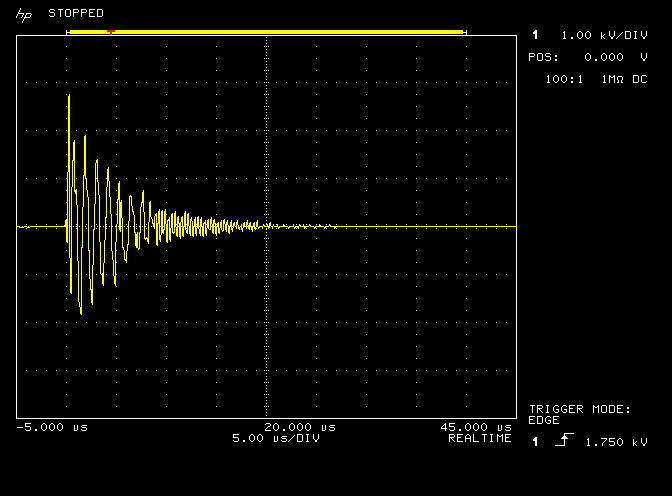

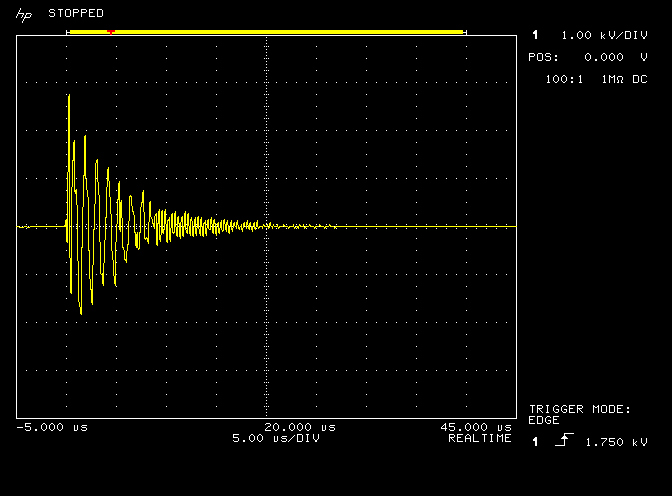

The second and preferred method is the SCR based power controller, (similar to a light-dimmer controller but more powerful), which controls the on part of the sinusoidal cycle, and hence controls the overall power delivered to the transformer, which effectively restricts the core saturation whilst providing variable control of the output power. Suitable SCRs are very easily and cheaply available, and a complete unit with an output power of up to 3kW has been used in the HV supply. The disadvantage of the SCR is that the output is no longer a sine wave, but rather a distorted waveform that represents a small part of the total cycle. This has however provided some unexpected benefit in burst and impulse modes that will be discussed in the generator posts, but suffice to say here that the fast SCR turn-off can create very large voltage spikes in the MOT primary as the field collapses, which in turn produces strong impulses in the secondary at the line frequency. These impulses in the secondary, when fed directly to the experiment without a capacitor tank circuit, acts as one method of generating a non-linear trigger for a displacement event.

When working directly with the experiment at hand it is not convenient to keep walking backwards and forwards to the power supply to adjust power level or turn on or off the supply. To enable more distant control of the SCR the variable resistor used to control the power level was removed from the SCR circuit, and positioned in a small plastic box along with an on-off switch. The control box was then attached to the SCR via a long two-wire mains lead (5m), where on-off function is created by switching a higher resistance into the two-wire line, and hence holding the SCR in the off condition, which is also the case if the remote box is disconnected from the SCR power controller. Power control is affected from the variable resistor by reducing the resistance from 500kΩ down to 0Ω, which progressively turns the SCR on for a proportion of the ac line cycle.

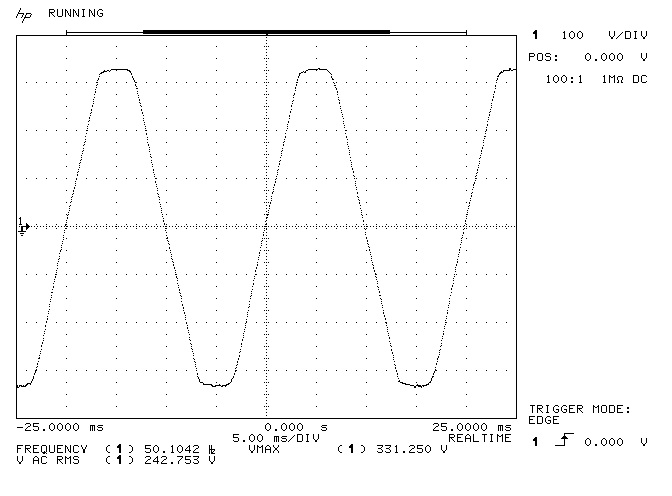

Figures 3 below show waveforms from the HV supply at a range of different points in the high voltage supply, and including the high voltage rectifier and tank capacitor at the output to form a load.

The output of the SCR power controller is passed through a system of connections to allow the MOTs to either be driven directly from an external source as required, or by direct connection to the SCR. Each individual MOT can be switched independently to the SCR output allowing the transformers to be used individually or combined in parallel or series combinations to increase the available output current or voltage. The output of the SCR is also fed to a 25W mains incandescent lamp which indicates clearly to the operator when voltage is applied to the input of the one or more of the MOTs. This is a simple but important safety factor when working in the experimental environment, and is a rapid but not exhaustive check to the running status of the high voltage supply. It must also always be remembered that considerable energy can be stored in the generator components, such as tank capacitors etc., and that a no visible lamp output is not a direct indication that it is safe to touch any part of the high voltage circuits prior to the appropriate discharge procedures.

The MOT is a cheaply manufactured component with minimum materials and quality, and hence the high voltage winding isolation to the steel core will not usually withstand voltages in excess of ~1.5 times the nominal designed output. This makes it difficult to combine MOTs in series where the core connected terminal of the secondary has been detached from the core in order to float the secondary, whilst keeping the steel core connected to earth for safety purposes. In this configuration the open-circuit peak voltage of the secondary can reach almost ~6kV from 2 series connected MOTs, which can easily arc-over to the steel core through the secondary insulation. When allowed to happen for any period of time the secondary coil is easily permanently damaged.

To overcome this problem and to enable two MOTs to be connected safely in series (both cores earthed), the MOTs are connected in series anti-phase, or center-tapped arrangement. In this configuration the two cores are connected together to earth, which also means the two core connected ends of the two secondary coils are also connected to earth. The primaries of the two transformers are then connected in reverse phase to each other, (as shown in the circuit diagram), such that one transformer produces +VHT out, and the other transformer produces -VHT out. The total output voltage of the series connected secondaries is 2VHT, and the maximum secondary to core voltage on either transformer is only VHT, preventing any secondary to core breakdown.

Of the three available MOTs in the high voltage supply, two are centre-tap connected, and one is floated from the core. This combination was found to be most flexible where the centre-tapped pair are suitable for driving spark gap based generators, and the floated individual is most suitable for driving vacuum tube based generators and if required in conjunction with a diode voltage doubler. In some generator configurations it was necessary to reduce the secondary current using a power resistor, which also in some specific cases helps to stabilise changes in power factor when driving varying or fluctuating high impedance loads from the generator outputs. When and where required a fan-cooled 100Ω 100W wire-wound resistor was used to reduce secondary currents and stabilise the supply output impedance to the next stage. For sustained outputs the MOTs and output components are cooled using a pair of low voltage fans which are manually switched as required.

Overall the high voltage supply has proved to be robust and versatile in providing high voltage in a variety of configurations to a range of different types of generator circuits. The design of the high voltage supply makes it easy to use in the experiments, with accurate and remote control of the output, and constructed with basic and readily available components.

Click here to continue to the 811A vacuum tube generator.

1. Dollard, E. & Lindemann, P. & Brown, T., Tesla’s Longitudinal Electricity, Borderland Sciences Video, 1987.

2. Wokoun, P., Investigations on Using a Salvaged Microwave Oven Transformer, 2003, KH6GRT Website